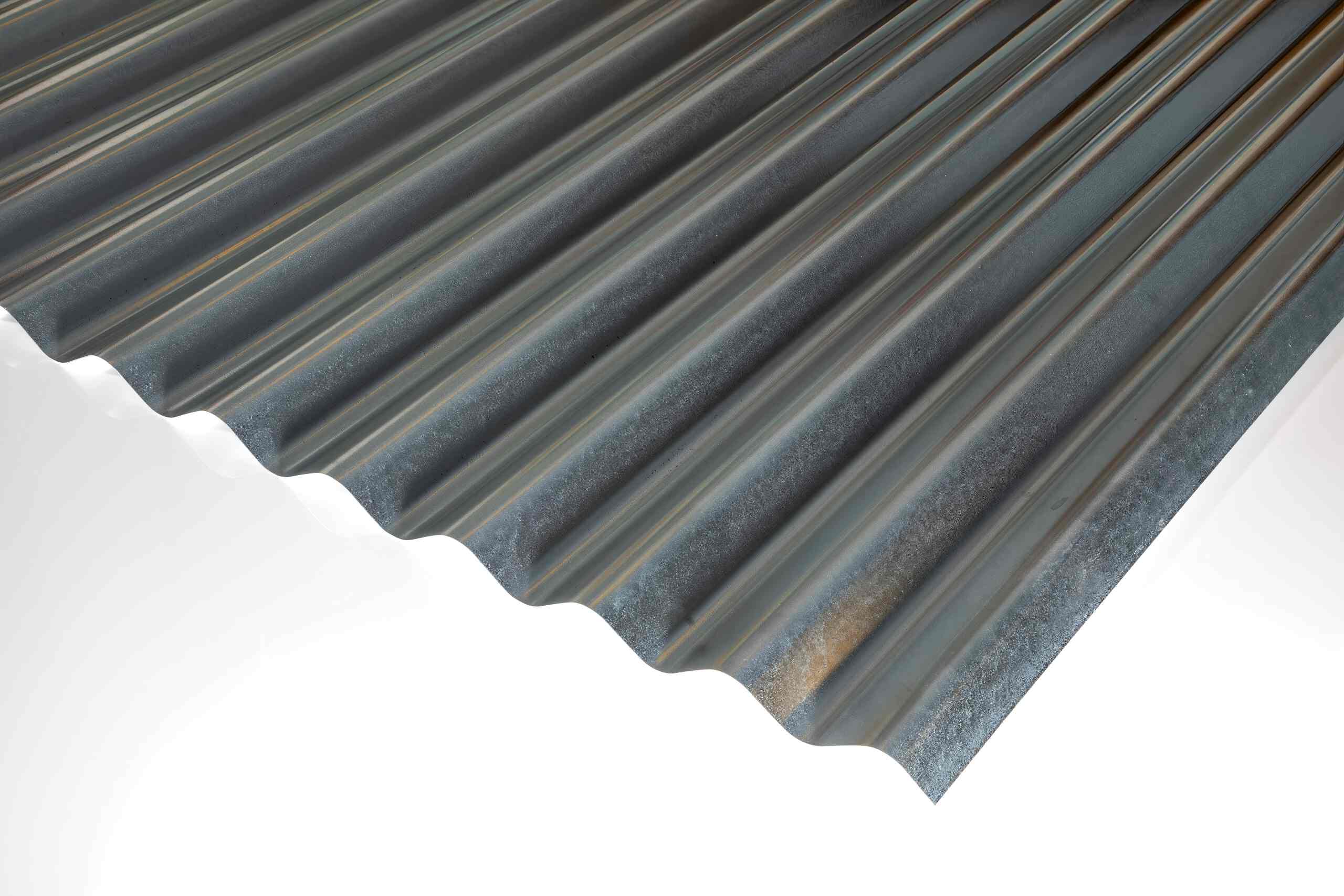

HONGSHENG'S Galvanized Steel is obtained by the process of surface cleaning, annealing, galvanize coating, drying, respectively, of Fullhard product rolled to the final thickness. Optionally, tempering, lubrication and passivation applications are also made.

It is applied on both sides of cold-rolled steel sheet using a precise continuous hot dip process and has excellent corrosion resistance, paintability, and workability due to zinc’s characteristic of self sacrifice.

The hot-dip galvanizing process originated in the mid -18th century, with the first industrial application of hot-dip galvanizing by Sorrel in France in 1836, and the invention of the continuous hot-dip galvanizing line by Sengemeier, a Pole, in 1931, which led to the continuous production of steel strip.

HONGSHENG's galvanizing lines have high production efficiency, precise control of plating thickness. They can provide products with smooth surface quality and low maintenance cost, suitable for home appliances and automobile exterior panels.

The hot-dip coated deep-drawing steels of the DX grade family according to EN 10346 offer excellent forming properties and good aging resistance. The mechanical properties of the individual deep-drawing steel grades are characterized by the level of yield strength and tensile strength as well as by assured minimum values of elongation at break.

DX51D | 1.0917

Grade DX51D is a machine folding grade and is suitable for simple craft forming work as well as for the production of simple profile shapes. DX51D is generally applicable in mechanical and structural engineering, e.g. for ventilation technology, air conditioning systems, switch cabinets, electrical industry, household appliances and steel furniture.

DX52D | 1.0918

Grade DX52D is a drawing grade and can be used for drawing, stamping and profiling difficult parts.

DX53D | 1.0951

Grade DX53D is a deep-drawing grade that meets high demands on formability and is particularly suitable for the production of difficult profiles with greater thicknesses.

The hot-dip coated steels of the S grade family according to EN 10346 are used in civil engineering. The steels are classified according to increasing values of the minimum proof stress Rp0.2 from 220 to 550 MPa. Hot-dip coated structural steels are used in construction, mechanical engineering and vehicle construction.

S250GD | 1.0242

Grade S250GD is a structural steel with a yield strength of at least 250 MPa.

S350GD | 1.0529

Grade S350GD is a structural steel with a yield strength of at least 350 MPa.

S550GD | 1.0531

Grade S550GD is a structural steel with a yield strength of at least 550 MPa.

OTHER PRODUCTS

CUSTOMER SERVICES

Customer Services

Customer Services

HONGSHENG Laboratories

HONGSHENG Laboratories

leave a message

Scan to Wechat :

Scan to WhatsApp :